HOW OUR T-SHIRTS ARE MADE

The World’s finest cotton T-shirts are given special attention by the team at The Cotton® Studios in London. They are made with the world’s finest quality cotton source and best possible procedures to create the World’s finest cotton t-shirts for our valuable customers.

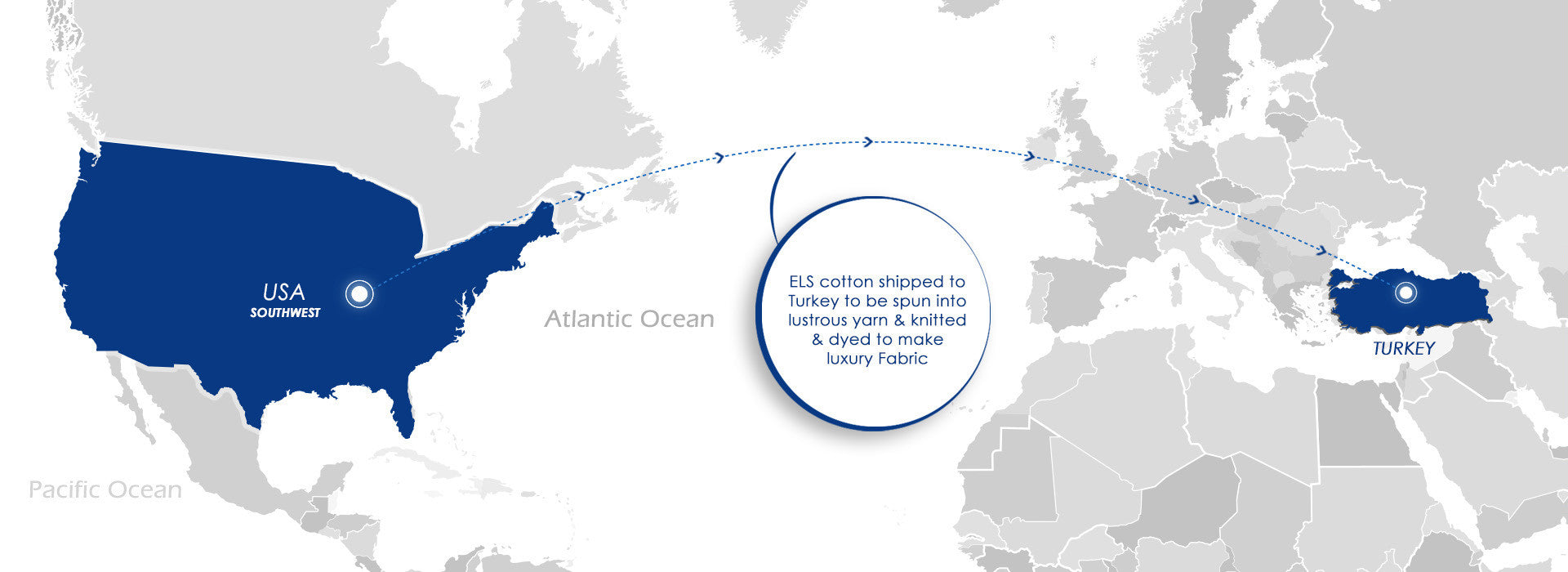

Our extra-long staple (ELS) cotton is grown in the United States of America, primarily in the southwest. This cotton is always cultivated and picked by hand as there is a risk of discoloration and destruction of the crop in machine harvesting.

It is then packaged and shipped to Turkey to be spun. Cotton fibres are twisted together to make a yarn. Higher number of twists produces a strong yarn whereas a low number of twist produces softer and more lustrous yarn.

The yarn is then ready for weaving and knitting. The yarn which runs in a vertical direction on the loom is known as the warp whereas the yarn which runs across in a horizontal direction interlocking with the warp is known as the weft. It then undergoes the four basic processes of the loom which include shedding, picking, beating and taking up or letting off. This is how a cloth is constructed through the technique of weaving.

The second prevalent method of fabric construction after weaving is known as knitting. In recent years this method has also gained tremendous popularity. Different kinds of needles are used to produce different kinds of knitted fabric. Two main variations of knitting are known as: weft knitting and warp knitting. Knitting is often done by hands but for mass production knitting machines are also used which are known as knitting frames and knitting looms. These can be hand driven or motor powered.

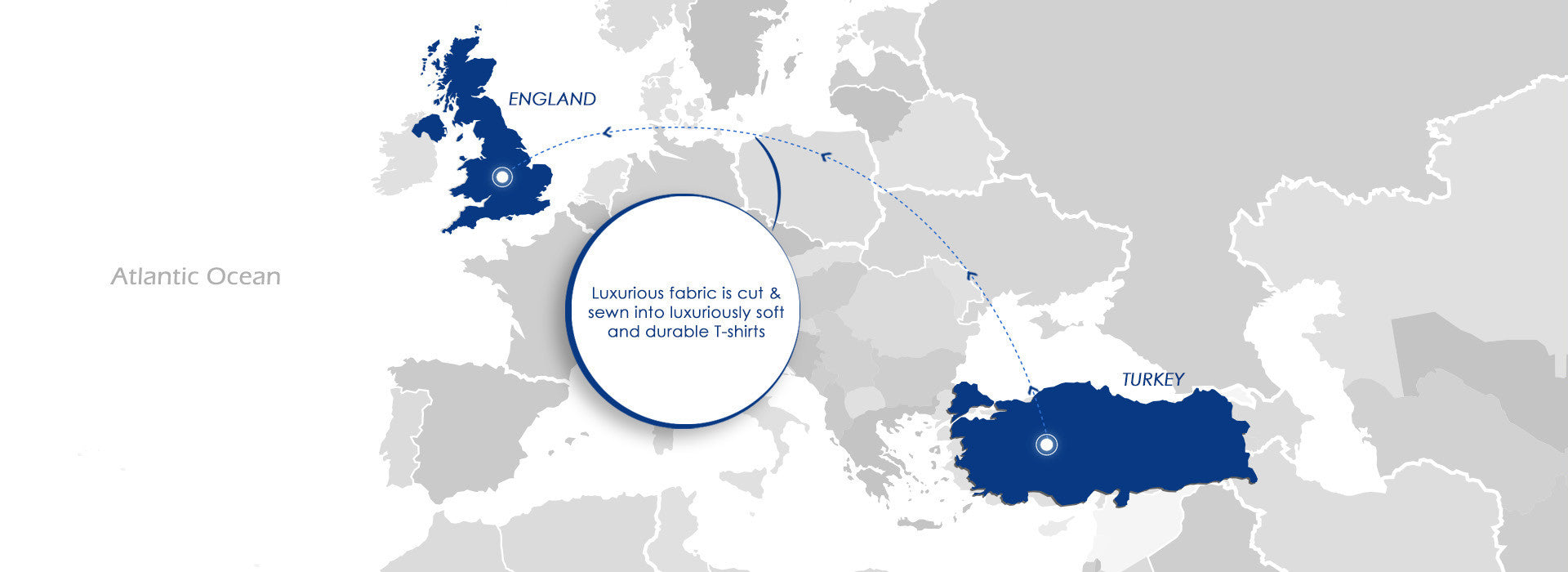

Once our fabric is woven or knitted it undergoes the process of dyeing. Our devoted team at the Fabric Manufacturer makes sure to treat the fabric for high durability, pilling resistance and moisture absorbance. All of the above procedures take place in Turkey. Once the product is packed it is shipped to Leicester England.

With the help of small artisan factories the fabric and pattern is cut. Subsequently it is stitched and the label is crafted to the shirt. The product finishing is done while keeping every intricate detail in mind. The finished garment is then ready to travel to Nottingham England for its logo pattern or embroidery.

The finalized garment is sent to The Cotton® Studio in London for its detail examination & quality assurance. This luxurious hand checked garment is then packed in luxurious packaging and is now ready to be dispatched to its loyal customer.