HOW OUR SHIRTS ARE MADE

Here at The Cotton® London we give utmost attention to our formal and casual shirt collections. We believe good quality shirts are made with the finest materials, and the best manufacturing possible. We do rigorous quality checks throughout the shirt’s life cycle to ensure it is of the finest quality for our customers.

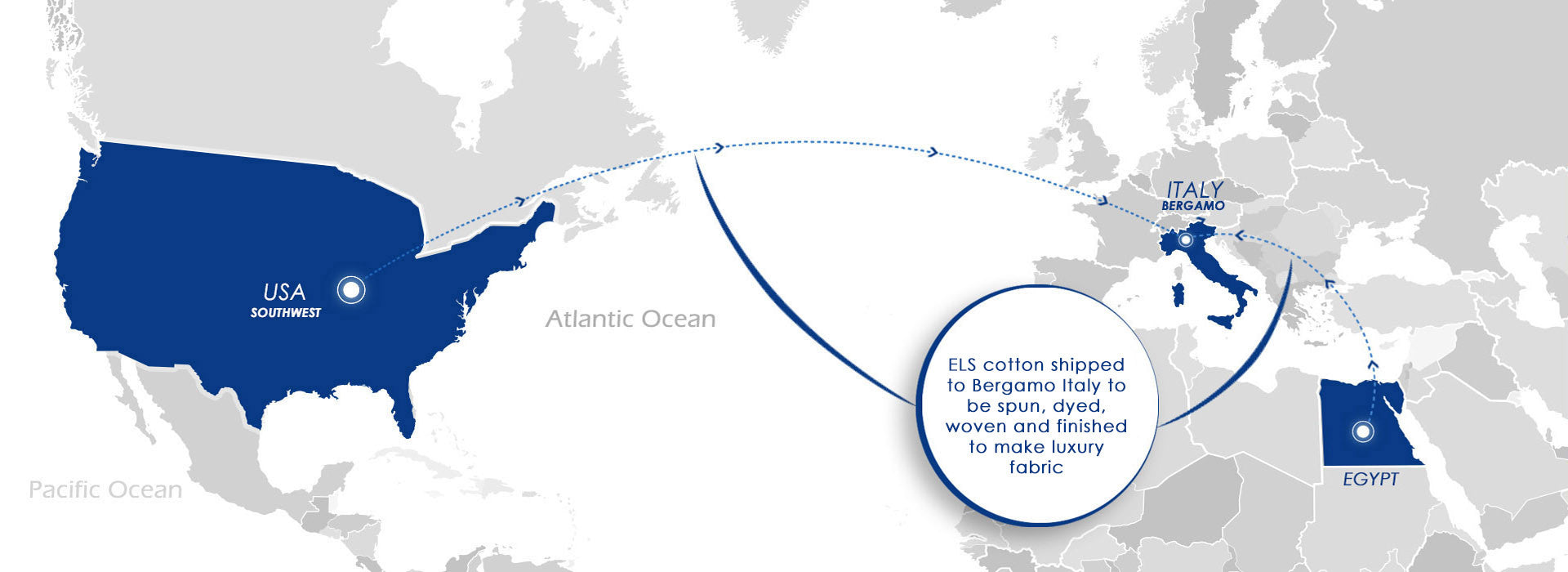

We only use extra-long staple (ELS) cotton for our shirts. All of our cotton is grown either in the United States of America, primarily in the southwest or it is grown in Egypt to create the most highly precious Giza 45 Egyptian cotton fibre. Both these cotton sources are always cultivated and hand-picked as there is a risk of discoloration and destruction of the crop in machine harvesting. This also makes the raw cotton considerably costly.

Once packed this cotton is shipped to Bergamo Italy to be spun, dyed, woven and finished. Spinning involves the long cotton staples flaked, carded, sorted, pressed, stretched, pressed again and twisted into lengthy yarn that is smooth and durable with minimum hairiness.

After removing impurities from the yarn it is dyed which takes around eight to twelve hours. It is then washed, oxidized and extra dye is eliminated. Lastly it is dried using a combination of centrifuge and radio frequency.

The next step is weaving of the yarns to create the fabric. The yarn which runs in a vertical direction on the loom is known as the warp whereas the yarn which runs across in a horizontal direction interlocking with the warp is known as the weft. It then undergoes the four basic processes of the loom which include shedding, picking, beating and taking up or letting off. This is how a cloth is constructed through the technique of weaving.

Lastly the fabric is re-purified and any wax, oils or residues that may have been produced in earlier stages is cleaned off. The hairy surface fibres are burnt off to create a smooth texture. The cloth is then steamed to fix the colour and prints and to ensure that fibre doesn’t shrink.

Once finished the fabric is checked for defects through a series of physical and chemical tests that monitor how the fabric reacts to washing, rubbing and other stress tests.

The finished quality checked fabric then travels to Bari in south Italy. Here our shirt makers use CAD (Computer aided design) to create pattern models. With the use of computer generated pattern models, clothing pattern maker professionals are able to save time, money and effort. Adjustments can be all done with a click of a button and they can develop multiple patterns at a time.

Using the CAD pattern models, the plotter prints out the pattern on the fabric and the pattern is then cut with precision and perfection by highly skilled shirt makers.

All the pieces of fabric, collars and cuffs are put together in sets and are sewn together according to the standard specifications for our ready-to-wear collection. Using beautiful mother-of-pearl buttons, buttons holes and buttons are stitched on to the shirts by hand or by machines. We make sure they are sewn with strong crossed-lock stitching to prevent it from getting loose ever. The manufactured shirts are then trimmed, labelled with our label and monograms. Each shirt is carefully inspected for defects and signed for quality check before being shipped to London, UK.

The finalized garment is received at The Cotton Studio in London for its detail examination & quality assurance. This luxurious hand checked garment is then packed in luxurious packaging, ready to be delivered to its loyal customer.